Description

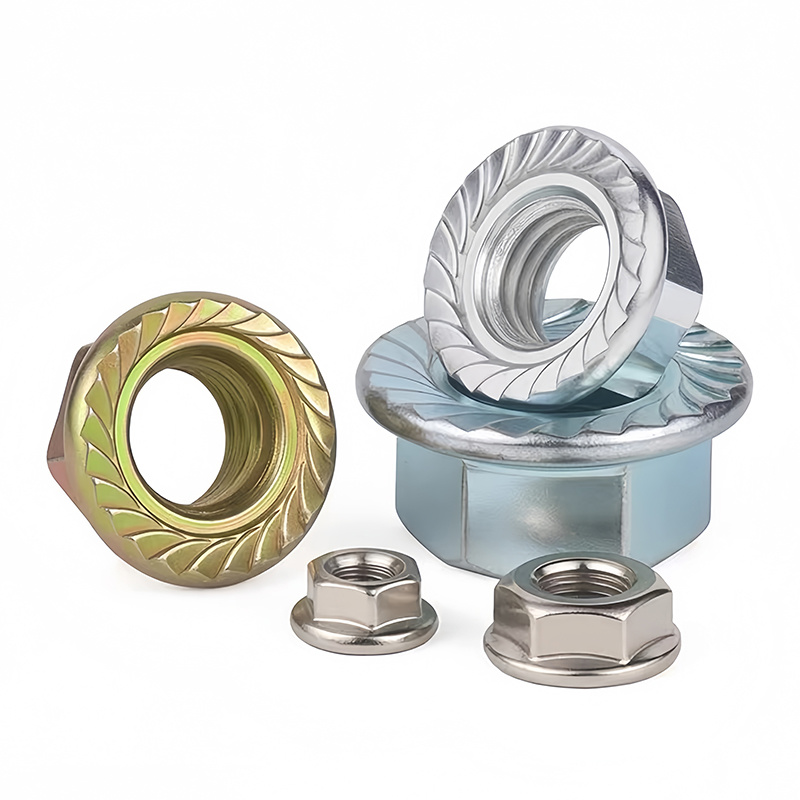

Spring washers are standard components widely used in both load-bearing and non-load-bearing structures of mechanical products, mainly to prevent nuts from loosening.

Spring washers, often referred to as spring washers in the screw industry, are installed under nuts to prevent them from loosening. They are widely used in both load-bearing and non-load-bearing structures of general mechanical products. Their features include low cost and easy installation, making them suitable for areas with frequent assembly and disassembly. The basic function of a spring washer is to apply a force to the nut after it is tightened, increasing the friction between the nut and the bolt. This is a protective measure added to prevent the loosening of the fastening bolts caused by the vibration of the operating equipment. The anti-loosening principle of the spring washer is that after flattening the spring washer, it will generate a continuous elastic force, maintaining a continuous friction force between the threaded connection pair of the nut and the bolt, generating a resistance moment, thereby preventing the nut from loosening. Meanwhile, the sharp corners at the openings of the spring washers are respectively embedded into the surfaces of the bolts and the connected parts, thereby preventing the bolts from rotating relative to the connected parts

Qualifications and Honors

Company environment

Packaging and transportation

Specializing in the production of various conveyor belts, conveying machinery, and accessories, the company is committed to delivering efficient and reliable material handling solutions to global customers. Its products are widely used in industries such as metallurgy, mining, building materials, power generation, chemical, ports, and grain, helping enterprises achieve automated and intelligent production processes.

Customized Process

Order Notes

To meet diverse industry needs, our products are categorized into multiple specifications based on material handling requirements and operational environments:Standard, Heat-Resistant, Acid/Alkali-Resistant, Oil-Resistant, Cold-Resistant, and Flame-Retardant types.

Goods will be strictly tested before delivery, please check carefully after receiving the goods, if there is any problem, please contact us in time.

Online communication

Provide custom drawings

Merchant quotation

Sign a contract

Processing and production

Packaging and distribution

Confirm receipt of goods

Successful transaction

Can you accept small quantities?

Yes, accept small quantity, fast delivery

Do you have pre-shipment inspection procedures?

Yes, we always test the products before delivery.

Can I take samples for testing?

Yes, samples can be sent for testing before bulk ordering.

When is the delivery time?

Inventory orders within 7-15 days, for oem and odm orders, the specific time depends on the actual situation.

What are the terms of payment?

Wire transfer or letter of credit, Western Union, Alipay, etc.

What is the minimum order quantity?

It depends on the product.

Previous

Next

Spring Washer

You still doubt it? First get samples contact us!

subcategory

keyword

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!