Description

Shackles are various rigging and are a type of shackle used in mountain climbing.

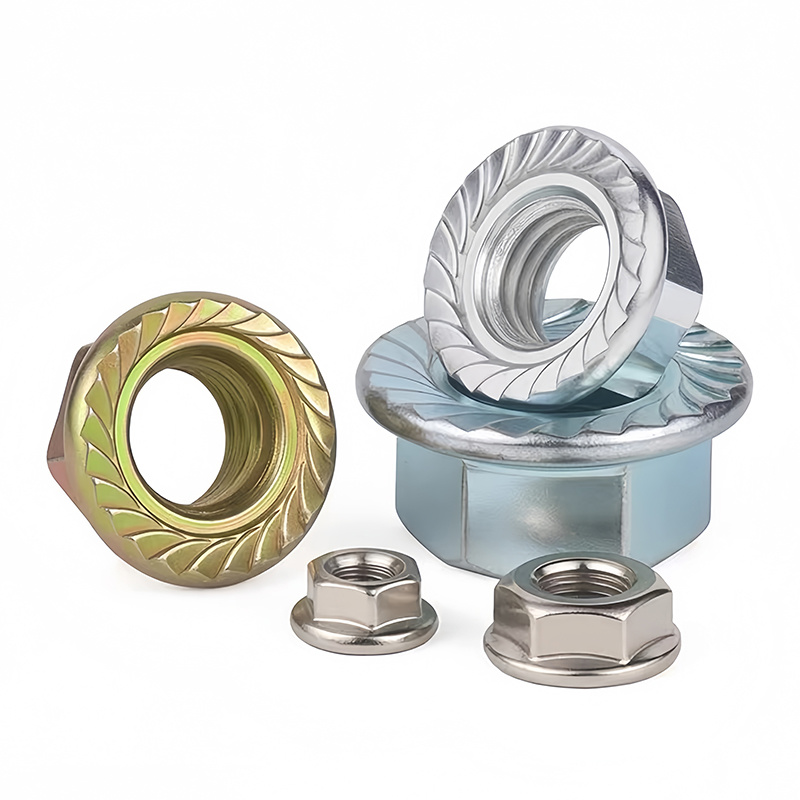

The commonly used shackles in the domestic market are generally classified into three categories according to production standards: national standard, American standard and Japanese standard. The American standard is the most commonly used one because it is widely applied due to its small size and large load-bearing capacity. Shackles are widely used in various industries such as power, metallurgy, petroleum, machinery, railway, chemical engineering, ports, mining, and construction. The shackles should be smooth and flat, and no defects such as cracks, sharp edges or overburning are allowed. Cast iron or cast steel shackles are strictly prohibited. Drilling or welding repairs should not be made on the shackles. After the permanent deformation of the buckle body and the pin shaft, they shall not be repaired.

When in use, the buckle body and pins should be inspected to ensure they are not severely worn, deformed or have fatigue cracks. When in use, the lateral spacing must not be subjected to tensile force, and the shaft pins must be properly inserted with safety pins. After the shaft pins are correctly assembled, the width of the buckle body shall not be significantly reduced, and the threaded connection shall be good. The use of shackles must not exceed the specified safety load. The shackles were tested with twice the safety load as the test load. The shaft pin shall not have permanent deformation and can rotate freely after being loosened. The shackles can undergo sampling reliability tests. The load is twice the test load. The shackles must not break or deform that would cause them to lose their load-bearing capacity. The safety loads of the currently used shackles are all approved at grade M (4). The strength grade, safety load and other marks should be marked on the buckle body.

Qualifications and Honors

Company environment

Packaging and transportation

Specializing in the production of various conveyor belts, conveying machinery, and accessories, the company is committed to delivering efficient and reliable material handling solutions to global customers. Its products are widely used in industries such as metallurgy, mining, building materials, power generation, chemical, ports, and grain, helping enterprises achieve automated and intelligent production processes.

Customized Process

Order Notes

To meet diverse industry needs, our products are categorized into multiple specifications based on material handling requirements and operational environments:Standard, Heat-Resistant, Acid/Alkali-Resistant, Oil-Resistant, Cold-Resistant, and Flame-Retardant types.

Goods will be strictly tested before delivery, please check carefully after receiving the goods, if there is any problem, please contact us in time.

Online communication

Provide custom drawings

Merchant quotation

Sign a contract

Processing and production

Packaging and distribution

Confirm receipt of goods

Successful transaction

Can you accept small quantities?

Yes, accept small quantity, fast delivery

Do you have pre-shipment inspection procedures?

Yes, we always test the products before delivery.

Can I take samples for testing?

Yes, samples can be sent for testing before bulk ordering.

When is the delivery time?

Inventory orders within 7-15 days, for oem and odm orders, the specific time depends on the actual situation.

What are the terms of payment?

Wire transfer or letter of credit, Western Union, Alipay, etc.

What is the minimum order quantity?

It depends on the product.

Previous

Next

Shackle

You still doubt it? First get samples contact us!

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!